About Changzhou Giken

Changzhou Giken founded in October 1994, is a subsidiary of Giken Sakata (S) Limited. In February 1993, Giken Sakata (S) Limited was listed on the Singapore Stock Exchange and subsequently transferred to GSS Energy Limited in February 2015.

Qualification

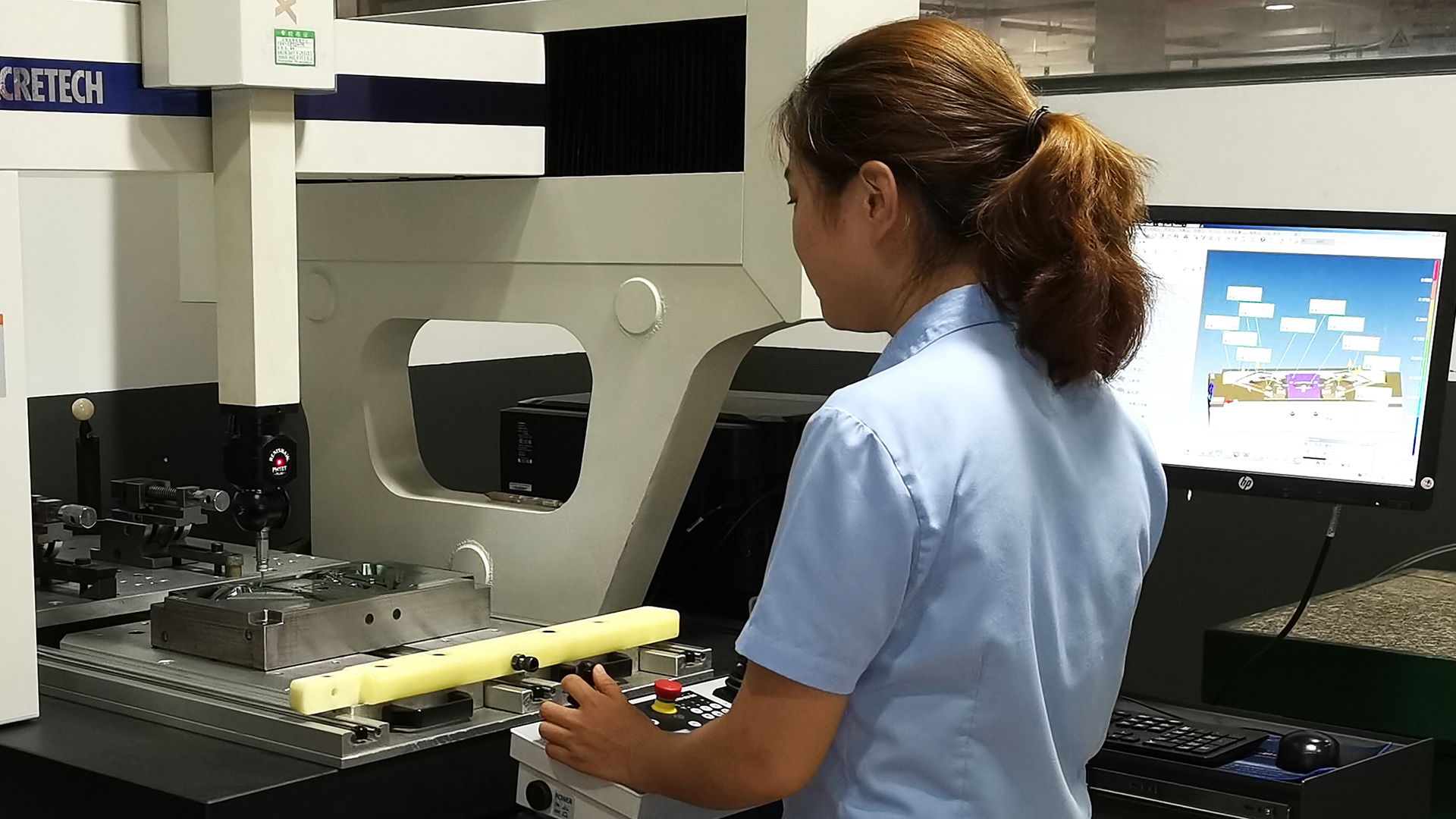

At Changzhou Giken, we created Giken Quality Systems to ensure total customer satisfaction. We pride ourselves in consistently meeting and exceeding customer expectations. All employees place their topmost priority on quality control and service excellence.

Facilities

The group provides vertical integration services, including product design and development, precision parts processing and manufacturing, product production, product assembly, etc.

Market

- Automotive

- Medical Equipment

- Consumer Electronics

- Home Appliances

- Industrial

- Gaming & Toys

The automotive industry comprises of a wide range of companies and organizations that are involved in design, development, manufacturing, marketing and selling of motor vehicles. It is one of the world's most important economic sectors by revenue.

read more

The healthcare & medical industry is an economic sector that provides goods and services to treat patients with curative, preventive, rehabilitative, and palliative care.

Consumer electronics refer to any device containing an electronics circuit board that is designed to be purchased and used by end users or consumers for daily and non-commercial/professional purposes.

read more

Home appliances are electrical/mechanical machines which accomplish some household functions such as cooking, cleaning, or food preservation

read more

Industrial is a segment of the economy involving the manufacturing and transportation of products.

In the toy making industry, different materials like wood, clay, paper, and plastic are used in its production. The gaming and toy making industry are essential to young children when it comes to growing up and learning about the world around us.

Service

- Design

- Tooling Design & Fabrication

- Injection Moulding

- Low Pressure Moulding

- PCB Assembly

- Product Assembly

- Precision Machining

- Tempo Printing

- Testing

In today’s rapidly changing environment, apart from having a good designed product, launching a new product to the market timely is a key factor to ensure its success. At Giken, we provide a comprehensive set of solutions for product design, which includes Industrial Design (ID), mechanical design, electronic design, software design and various kinds of wireless solutions. We believe in providing our customers with the best design solutions and in meeting their needs and deliver on schedule.

Our team of experienced product development engineers will ensure the design are put to reality and in accordance to our customer specifications and expectations.read more

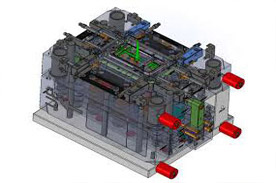

A good piece of design requires support of precision tooling die to bring the design to reality. At Giken, we have a dedicated team of experienced tooling designers and mould makers that can handle tooling from 30 Ton to 500 Ton or more. Prior to the design stage, it is instrumental to understand the tooling requirements from our customers. With the careful selection of design and materials combined with the right tooling, we seek to provide the most competitive pricing in the market.

Prior to tooling die fabrication, our emphasis is to conduct Design For Manufacturing (DFM) study and mould flow simulation to ensure our tooling is error-free during mass-production.read more

Precision injection moulding has been one of our pioneer technology of our business unit since 1992. We have full range of injection machine ranging from 18 Ton to 530 Ton to meet our customer needs. Our team of professionals with vast experience and various expertise have been with us as long as the company was started. They are more than capable of meeting all the new product challenges. We are most familiar with and largely experienced in most of the plastic materials used in engineering processes such as ABS, PC, PA, POM, PVC, PSU, ICP, PPSU, PBT, PPS, PP + Gamma Resistance, and glass-filled high-temp Nylon.

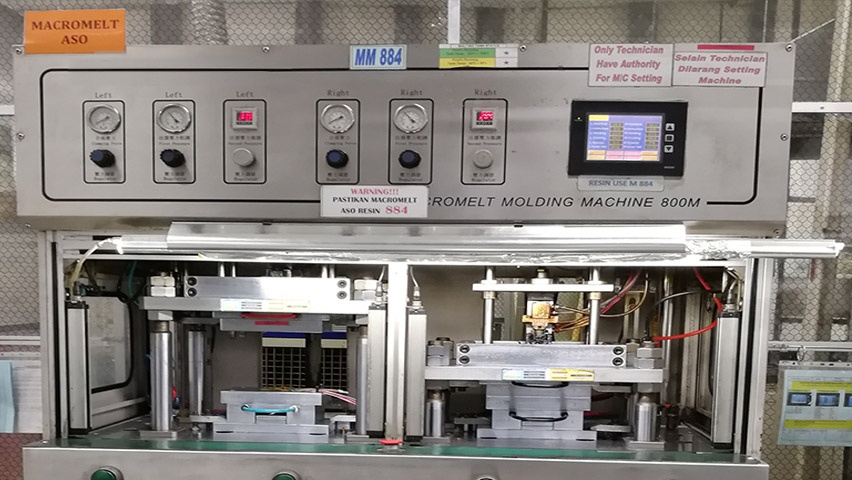

Low Pressure Injection Moulding is the process of over-moulding electronic devices with polyamides to protect them. The PCB assembly or electronic part is placed in a specially manufactured aluminium mould tool, and completely surrounded with a liquid compound that effectively forms the housing for the device. Giken has developed the know-how for many years and we are supplying the completed products to our satisfied customer. We provide custom-made design to meet our customer’s product design and requirements at a competitive price. We are always innovating and inventing our processes to reduce costs so that we can offer a better pricing for our customer.read more

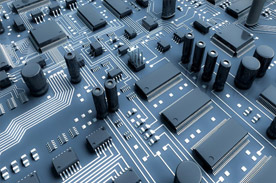

Giken offers one-stop high quality PCB Assembly Services with flexible volume project since 1994. We can provide from start-to-finish solution to meet all our customer needs. With more than 20 years of experience and established relationships with authorized electronic components manufacturers and distributors, we will always have the advantages to get the best, fastest and highest quality service and support from them.

We placed high emphasis on “Quality” when it comes to production. We have a strategic and systematic plan on staff training to ensure that the finished products were delivered with the highest quality and ZERO defects. Besides, we also have professional and experienced engineering teams that are able to support our customers in any aspects of the projects. read more

Along with Giken's design and manufacturing facilities, we have amassed a wealth of product assembly capabilities serving different customers in multiple industries. Capabilities that start with parts checking and quality control, packaging, labelling and distribution. We welcome any range of assembly projects from assemble to entire products or single module only.

We have many interesting portfolio since 1991, please find some of the Industry/Market segment that we served below:read more

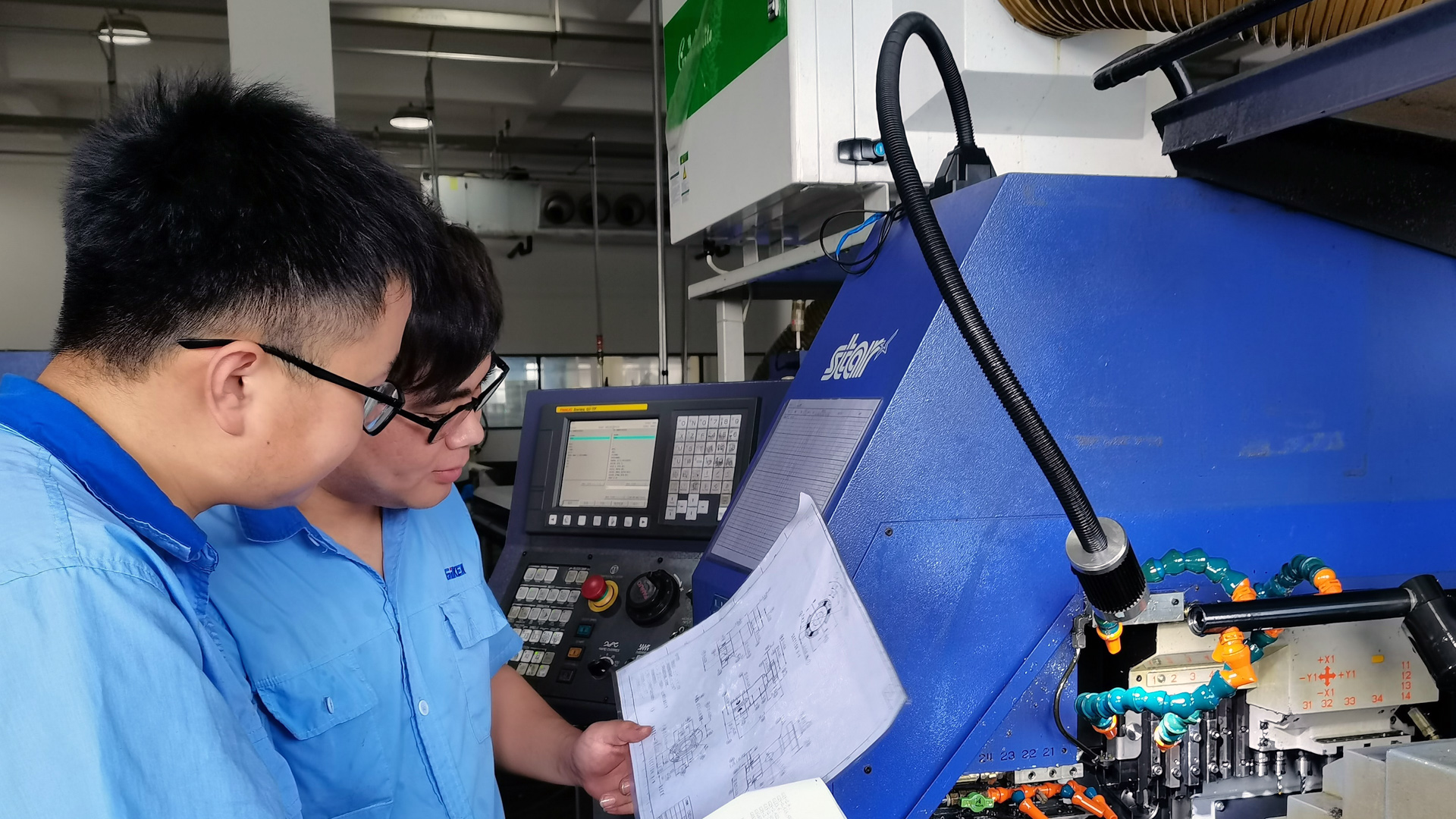

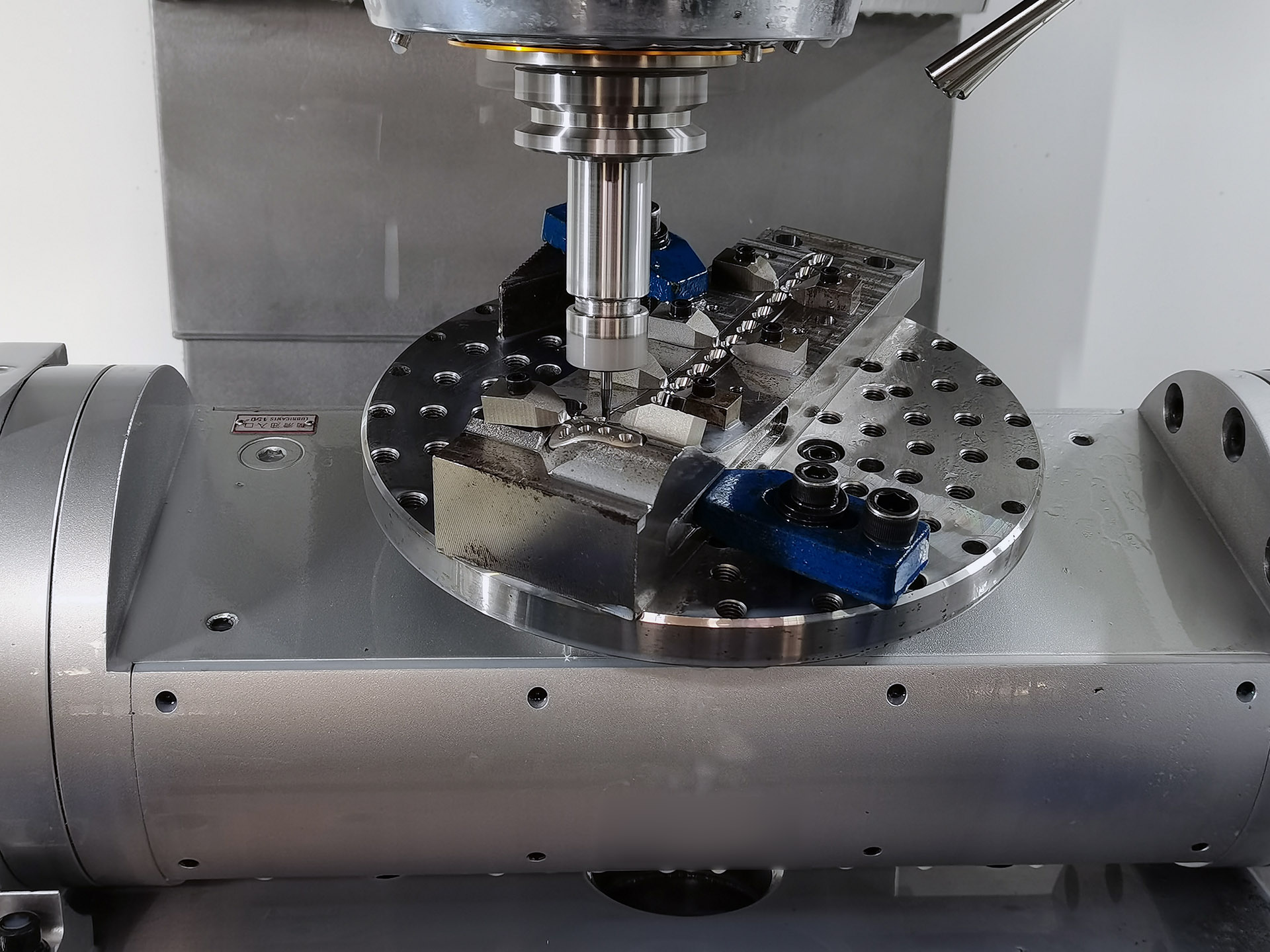

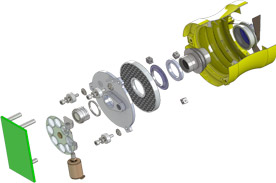

Precision Machining is a process to remove material from a workpiece while holding close tolerance finishes. Giken has been involved in precision machining industries for more than 30 years. With these years’ of experience and knowledge, Giken is able to provide world class engineering solutions to a wide range of industries that include Medical, Automotive, Semiconductor, Home Appliances, Toy, Pump, Motor, Oil & Gas, Aerospace and etc.

read more

Value added services like adding detail on the finished product is one of our the most popular requests from our customers at Giken. Some of our customers require brand or logo printing on their products, we have in-house printing facilities that can fulfil your needs.

Pad / Tempo printing is one of our most common printing methods that can work on almost any surface and it is very cost effective. Besides, we also have silk screen facilities that can cope with large orders and the silk screen can be printed onto many different items with a very durable and long lasting effect. read more

As a one-stop service centre, we are able to support a variety of product testing if required. Below are some of the testing facilities that we provide:

read more